Pipe Bursting

Pipe Bursting is a method for replacing pipelines in situ while not interrupting above-ground activities. It’s a very cost-effective trenchless method to replace existing buried pipes. Pipe bursting is used to replace existing brittle pipes such as cast iron, asbestos, cement, clay, PVC, polyethylene and even reinforced concrete pipes, which can be upsized at the same time.

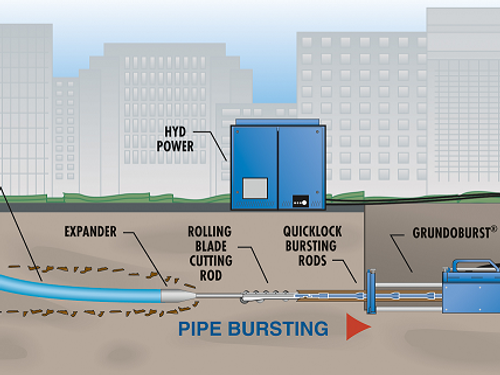

KB Contractors use Tracto-Technik grundoburst equipment with up to 80 tonnes of bursting power, utilising both hydraulic and pneumatic applications.

The pipe bursting method:

- A shaft is excavated approximately 4.0m x 1.5m over top of the existing pipe to be burst. Shoring will be installed if it’s over 1.5m deep. Any bypass pumping will be in place (if required) prior to this.

- An excavation is then complete at the pulling end which is where the pipe will be pulled through from. This is often at a MH in drainage works or at a structure (FH/valve) in water circumstances.

- The bursting machine is then lifted into the ground, the face shored up using steel plates and the rods sent down the existing line. Once at the pulling end, the lead rod is removed, and the cracking head placed on. This is either welded (if PE) or screwed (if restrain PVC pipe) to the length of pipe wishing to be pulled in.

- We then begin the pullback. The cracking head is wider than the pipe being pulled in, causing no damage to the outside of pipe as it’s being pulled through.

Why use KB Contractors for pipe bursting?

KB Contractors are an accredited contractor with Dunedin City Council, Invercargill City Council and Waitaki District Council. We offer this specialised trenchless method to replace existing buried pipes throughout Otago and Southland and even in Central Otago and can travel further afield if required. Email us today for more information on pipe bursting.

Contact Us

Contact Us