Steel Pipe Ramming

A trenchless method for installing steel pipes and casings

Steel pipe ramming is a recognised method of installing pipes. With a short set-up time and minor disruption to the ground surface, a wide range of pipes can be installed. Pipe ramming is a cost-effective and accurate alternative compared to conventional methods. Ramming tools are powered by compressed air and can be used for horizontal, vertical and angled applications.

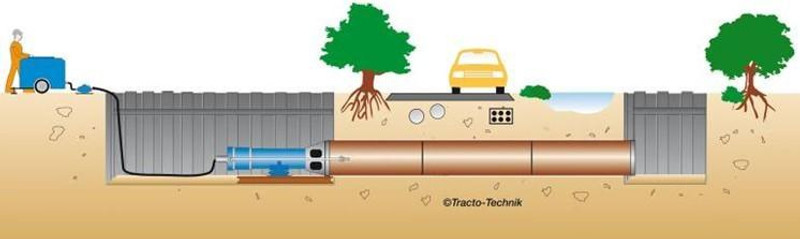

Steel pipe ramming is a method used for the trenchless installation of steel pipes and casings

A steel pipe is rammed under the ground, say underneath a road or railway line, to create a sleeve for the proposed pipeline to go through. To do this, an entry pit of 9 m is required to sit the 6 m long steel pipe in, as well as the ramming machine. A large compressor is connected which is what drives the ramming head. The rammer is sitting on timber blocks, all to grade, which then sends the steel pipe in at the correct angle or grade. Once the 6 m pipe is inserted, another can be welded on and the process repeated, depending on the length of the shot. The pipe will then need `jetted out‘ to remove all the fill from inside the steel pipe, this is done by using big jetting units with water blasters and hydrovac units to pick up the sludge that is removed.

Why use KB Contractors for steel pipe ramming?

KB Contractors are currently one of the only steel pipe ramming operators in the Otago and Southland region, as it’s specialist equipment, we will travel further afield if required. KB Contractors are members of Civil Contractors New Zealand, SiteWise, Site Safe, and ConstructSafe. With a team of around 50 personnel, we can be relied on to see projects through to completion. If you’d like more information, simply email us today.

Contact Us

Contact Us